Bitumen production process

Follow us on Twitter ![]()

Question, remark ? Contact us at contact@myengineeringtools.com

1. Introduction

2. Bitumen production process

1. Introduction

Bitumen is a main binder in road construction. It can be used to

bond the aggregates well together and form the asphalt.

Different types of bitumen can be used in the flexible pavement. The

main types of bitumen grades are VG bitumen and Pen bitumen which

can be used directly in the hot asphalt.

These two types of bitumen are produced directly from distillation

of crude oil. Generally, bitumen can be obtained by different ways

including straight run, air blowing, semi blowing, solvent

deasphalting and blending.

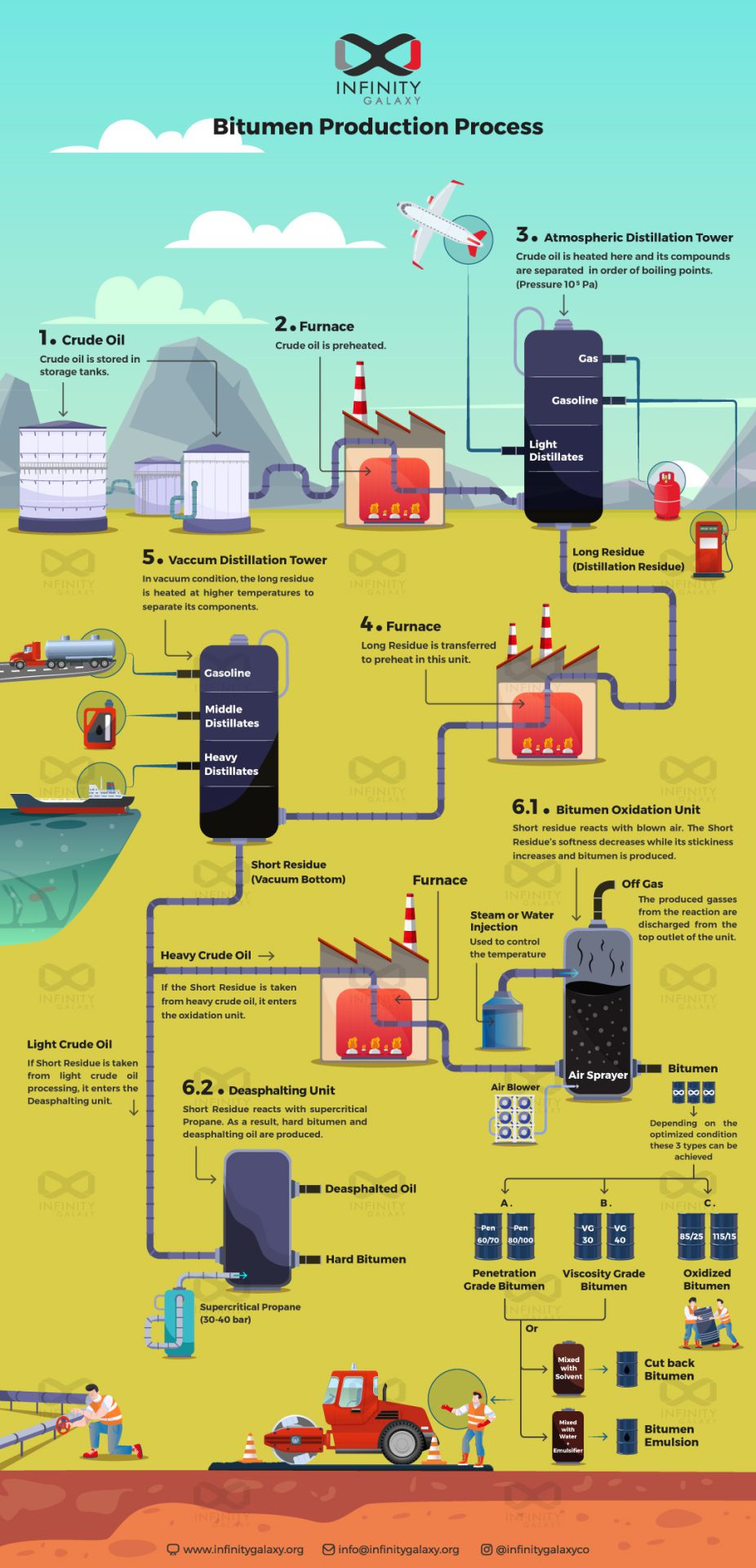

In the article below which is written by the Infinity Galaxy

team, you can read more details about bitumen production by

air blowing method. Also, the infographic can completely show you

the bitumen production process.

2. Bitumen production process

Bitumen production is a complex process that involves several stages

to convert crude oil into the final product suitable for various

applications, particularly in road construction. Understanding the

intricacies of this process is crucial for ensuring the quality and

consistency of the end product.

2.1 Crude Oil Distillation

The journey of bitumen production begins with the refining of crude

oil in a petroleum refinery. Crude oil, extracted from geological

formations, is a mixture of hydrocarbons of varying molecular

weights and compositions. In the first stage of the process, known

as crude oil distillation, the crude oil is heated in a distillation

unit, typically consisting of an atmospheric distillation tower.

As the crude oil is heated, it vaporizes and rises through the

tower, which contains multiple trays or stages. Each tray allows for

the separation of different components of the crude oil based on

their boiling points and molecular weights. Lighter components, such

as gasoline and diesel, vaporize at lower temperatures and are

collected from higher trays, while heavier components, including

bitumen precursors, remain in liquid form and are collected at the

bottom of the tower.

2.2 Vacuum Distillation

After the initial distillation process, the heavier residue known

as "long residue" or "residuum" is further processed in a vacuum

distillation tower. This residual fraction contains high molecular

weight hydrocarbons, including the precursors for bitumen

production. Vacuum distillation is conducted under reduced pressure

to lower the boiling point of the residual fraction, preventing

thermal degradation and reducing the risk of unwanted reactions.

During vacuum distillation, the long residue is heated and

vaporized, allowing for the separation of additional fractions based

on their boiling points. The heaviest fraction obtained from vacuum

distillation is known as "vacuum bottom," which serves as a primary

feedstock for bitumen production.

2.3 Air Blowing and Oxidation

The vacuum bottom obtained from the vacuum distillation tower

undergoes further processing through air blowing and oxidation to

convert it into bitumen. In the air blowing process, the vacuum

bottom is heated and exposed to controlled airflow, typically using

mild air or oxygen. This introduction of air leads to the oxidation

of bitumen precursors, resulting in changes to its chemical

composition and physical properties.

The oxidation process influences critical characteristics of the

final bitumen product, such as its softening point, penetration

degree, and viscosity. Through careful control of process

parameters, different grades of bitumen can be produced to meet

specific performance requirements for various applications,

including road construction.

2.4 Product Refinement and Packaging

Following the air blowing and oxidation steps, the resulting

bitumen undergoes quality control measures to ensure that it meets

industry standards and specifications. Quality testing may include

analyses of viscosity, penetration, ductility, and other physical

properties, as well as assessments of chemical composition and

performance characteristics.

Once the quality of the bitumen is confirmed, it is packaged into

containers suitable for distribution and storage. Common packaging

options include new steel drums or jumbo bags, which protect the

bitumen from contamination and ensure its integrity during

transportation to end-users, such as construction companies and

infrastructure developers.

3. Benefits of Air Blowing Method

The air blowing method, also known as the oxidation process, plays a pivotal role in the production of bitumen from vacuum bottom obtained during crude oil refining. This method offers several distinct advantages over alternative processes, making it a preferred choice for bitumen manufacturers. Understanding the benefits of the air blowing method is essential for optimizing bitumen production processes and enhancing product quality.

3.1 Enhanced Control over Bitumen Properties

One of the primary advantages of the air blowing method is its ability to provide precise control over the properties of the resulting bitumen. By adjusting key parameters such as temperature, airflow rate, and reaction time, manufacturers can tailor the characteristics of the bitumen to meet specific performance requirements. This level of control allows for the production of bitumen grades with varying viscosity, penetration, softening point, and other critical attributes, ensuring compatibility with diverse applications in road construction and other industries.

3.2 Modification of Physical and Chemical Properties

The oxidation process facilitated by air blowing induces significant changes in the molecular structure of bitumen precursors present in the vacuum bottom feedstock. Through controlled exposure to air or oxygen, chemical reactions occur, leading to the formation of oxygen-containing functional groups within the bitumen matrix. These structural modifications impart desirable properties to the bitumen, such as improved elasticity, adhesion, and resistance to aging and weathering. Additionally, oxidation facilitates the enhancement of thermal stability and rheological properties, further enhancing the performance and durability of the final bitumen product.

3.3 Versatility in Bitumen Grade Production

Another key benefit of the air blowing method is its versatility in producing a wide range of bitumen grades to suit varying application requirements. By manipulating process parameters and reaction conditions, manufacturers can generate different viscosity grades, penetration grades, and performance grades of bitumen. This flexibility allows for the customization of bitumen products tailored to specific climate conditions, traffic loads, and pavement specifications. Furthermore, the air blowing method enables the production of specialized bitumen variants, such as modified bitumen and polymer-modified bitumen, which exhibit enhanced properties for specialized applications in high-traffic areas, extreme weather environments, and challenging construction scenarios.

3.4 Environmental and Economic Considerations

In addition to its technical advantages, the air blowing method offers environmental and economic benefits compared to alternative bitumen production processes. The oxidation process consumes relatively less energy and generates fewer greenhouse gas emissions compared to alternative methods such as solvent extraction or thermal cracking. Furthermore, the utilization of vacuum bottom, a by-product of crude oil refining, as the primary feedstock for bitumen production enhances resource efficiency and reduces waste disposal requirements. Overall, the air blowing method contributes to sustainable manufacturing practices while maintaining cost competitiveness in the bitumen industry.

4. Quality Control and Testing Procedures

Ensuring the quality and consistency of bitumen products is paramount in meeting the stringent performance requirements of infrastructure projects, particularly in road construction. Quality control measures and rigorous testing procedures are integral components of the bitumen production process, allowing manufacturers to assess and verify the physical, chemical, and performance characteristics of the final product. This section provides an overview of the key quality control and testing procedures employed in bitumen production facilities.

4.1 Physical Properties Testing

Physical properties testing encompasses a range of analyses aimed

at evaluating the fundamental characteristics of bitumen related to

its mechanical behavior, durability, and suitability for specific

applications. Common physical properties tests conducted on bitumen

samples include:

Penetration Test: This test measures the consistency of bitumen by

determining the depth to which a standard needle penetrates the

material under specified conditions. Penetration values indicate the

hardness or softness of bitumen and are used to classify bitumen

into penetration grade categories.

Softening Point Test: The softening point of bitumen is determined

using methods such as the ring and ball apparatus, indicating the

temperature at which the bitumen softens and flows under

standardized conditions. This parameter is crucial for assessing the

temperature susceptibility and thermal stability of bitumen in

pavement applications.

Ductility Test: Ductility represents the ability of bitumen to

stretch without breaking and is evaluated by measuring the

elongation of a bitumen sample before failure under tension.

Ductility values provide insights into the flexibility and

deformation resistance of bitumen at different temperatures and

loading conditions.

Viscosity Test: Viscosity is a measure of bitumen's resistance to

flow and deformation, affecting its handling characteristics and

coating ability. Various viscosity testing methods, including

rotational viscometry and capillary viscometry, are employed to

quantify bitumen viscosity at specific temperatures and shear rates.

4.2 Chemical Composition Analysis

Chemical composition analysis plays a crucial role in assessing the

purity, stability, and performance-enhancing additives present in

bitumen formulations. Advanced analytical techniques are utilized to

characterize the molecular structure and functional groups within

bitumen samples, including:

Gas Chromatography-Mass Spectrometry (GC-MS): GC-MS analysis allows

for the identification and quantification of individual hydrocarbon

components present in bitumen, facilitating the determination of

molecular weight distribution, aromaticity, and heterogeneity.

Fourier Transform Infrared Spectroscopy (FTIR): FTIR spectroscopy

provides insights into the chemical bonding and functional groups

present in bitumen molecules, enabling the detection of oxidation

products, polymer additives, and other chemical modifiers.

4.3 Performance Testing

Performance testing evaluates the functional properties of bitumen

related to its behavior under simulated service conditions, such as

traffic loading, temperature variations, and moisture exposure.

Performance tests assess key parameters, including:

Rheological Properties: Dynamic Shear Rheometer (DSR) and Bending

Beam Rheometer (BBR) tests measure the viscoelastic behavior and

stiffness characteristics of bitumen at different temperatures and

loading frequencies, reflecting its deformation resistance and

fatigue performance.

Aging Resistance: Thin Film Oven Test (TFOT) and Pressure Aging

Vessel (PAV) tests simulate the effects of short-term and long-term

aging on bitumen samples, assessing their resistance to oxidative

aging, hardening, and embrittlement over time.

4.4 Quality Assurance Protocols

In addition to laboratory testing, quality assurance protocols are

implemented throughout the bitumen production process to ensure

compliance with industry standards and specifications. Quality

assurance measures include:

Process Control Monitoring: Continuous monitoring of process

parameters, such as temperature, pressure, and flow rates, ensures

the consistent production of bitumen with predetermined properties

and characteristics.

Batch Sampling and Analysis: Regular sampling of bitumen batches at

various stages of production allows for real-time quality assessment

and adjustment of process parameters to maintain product consistency

and integrity.

Certification and Compliance: Bitumen products undergo third-party

certification and compliance testing to validate their conformity

with national and international standards, ensuring their

suitability for use in construction projects and infrastructure

applications.