Pressure Safety Valve Basic Design guide - Gas flow,

P>101325 Pa

Pressure Relief Valve sizing

1. Introduction and warning

1. Introduction and warning

This design guide aims the reader at understanding the basic concepts behind the design and sizing of pressure relief valves but not at designing a valve for operational purposes. It is based on published sources but should not be considered for the detail design and selection / ordering of a pressure safety valve. Indeed, pressure safety valves are of utmost importance for the safety of the process, as they are most often the last resort to avoid an explosion, their design must therefore be done only by reputable companies. Only after having clearly defined the application, the position of the valve...etc... with the valve supplier, can he advise properly the plant operator and finalize the design of the valve.

The calculation below are derived from API520 and adapted from various sources. Those calculations are valid for a maximum allowable working pressure higher than 101325 Pa. Other types of services will require a different calculation code. API for example has other standards for low pressure valves. ASME or ISO have their own guidelines.

Note that this page is not discussing the choice and calculation of the design scenario, which is the process events leading to the maximum flow released through the valve. The required flow must be defined thanks to a risk analysis and process calculations.

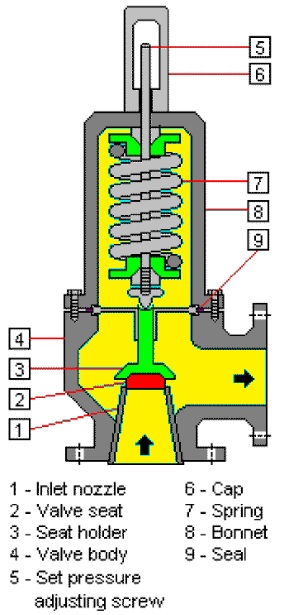

Figure 1 : Typical design of a pressure safety valve

2. API 520 relief valve sizing

How do you size a pressure safety valve?

2.1 Critical flow or subcritical flow

It is 1st necessary to determine how will be the flow in case of opening of the pressure relief valve. If the difference in between the pressure within the tank and pressure at the outlet of the valve is too important, the flow will be critical.

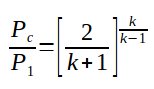

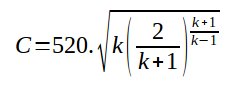

The critical pressure above which the flow becomes critical is calculated thanks to :

With :

Pc = critical pressure in kPa abs

P1 = upstream relieving pressure in kPa abs

P2 = downstream pressure in kPa abs

k = Cp/Cv

The following comparison must then be done to know if the flow will be sub-critical or critical and use the right formulae :

Critical flow| P2 ≤ Pc | Critical flow |

| P2 > Pc | Sub-critical flow |

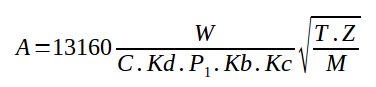

2.2 Critical flow Safety Valve sizing

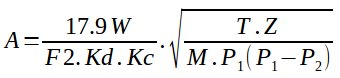

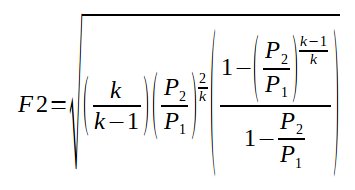

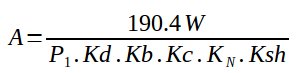

If the flow has been found to be critical, the following formula can be used :

W = required flow through the valve in kg/h

Kd = coefficient of discharge

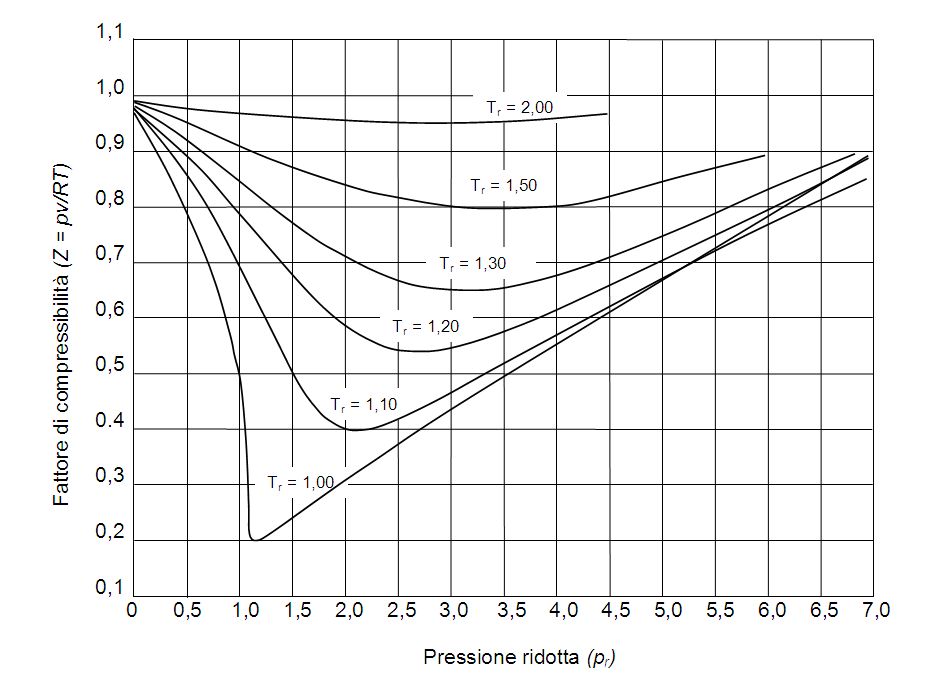

Z = compressibility factor of the gas at valve inlet conditions

M = molecular weight of the gas in kg/kmol

2.3 Sub-critical flow safety valve sizing

2.4 Special case of steam

3. Other calculation codes

4. Selection of Standard Relief Valves Orifice

Pressure safety valves symbols

The sizes of discharge areas is actually standardized and manufacturers will propose sizes accordingly. The Engineer, after having calculated the required size with the calculation sequence above, needs to select a standard size offering a discharge area higher than the calculated value.

| Standard letter / designation | Orifice area in in2 | Orifice area in cm2 |

| D | 0.110 | 0.71 |

| E | 0.196 | 1.26 |

| F | 0.307 | 1.98 |

| G | 0.503 | 3.24 |

| H | 0.785 | 5.06 |

| J | 1.28 | 8.30 |

| K | 1.84 | 11.85 |

| L | 2.85 | 18.40 |

| M | 3.600 | 23.23 |

| N | 4.340 | 28 |

| P | 6.38 | 41.16 |

| Q | 11.050 | 71.29 |

| R | 16 | 103.22 |

| T | 26 | 167.74 |

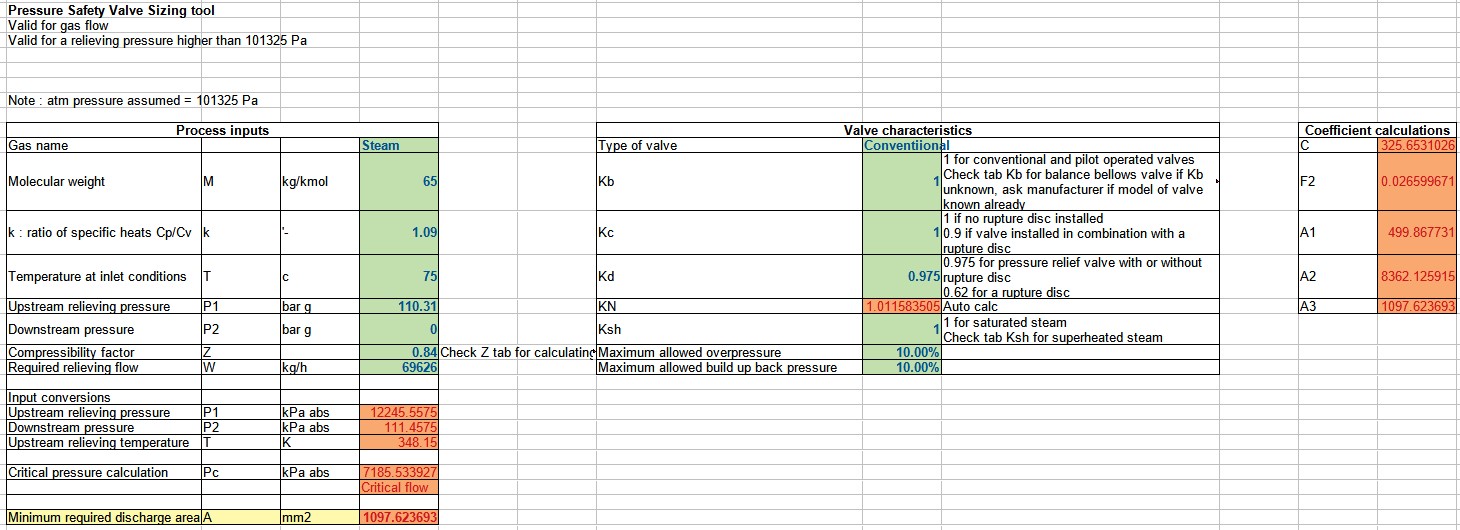

5. Pressure safety valve sizing calculation xls : Excel calculation tool

Note : the tool is for now only supporting gas flow in pressure :

WARNING

www.powderprocess.net and www.myengineeringtools.com cannot be held responsible for the use of the explanations, calculation and calculation tools presented here, the use of the information is at the user and its organization own risk and cost.