Mass Flowmeters (Coriolis Flowmeter): An Engineering Guide

Follow us on Twitter ![]()

Question, remark ? Contact us at contact@myengineeringtools.com

1. Introduction

2. Understanding Mass Flow Measurement

1. Introduction

It is usually very important in industrial processes to accurately measure flow. The capability to precisely quantify mass flow rates of liquids and gases will indeed directly influence the efficiency, quality, and safety of numerous applications across diverse sectors. Among the different flowmeter technologies available in the market, mass flow measurement based on Coriolis principle have gained a lot of traction over the last couple of decades.

This page is focusing specifically on Coriolis mass flowmeters.

2. Understanding Mass Flow Measurement

There is 2 ways to measure the quantity of a fluid that flows in a pipe, trying to measure directly the mass flow, or in the contrary trying to measure the volume of the liquid and then indirectly recalculate the mass flow. Distinguishing between mass flow rate and volumetric flow rate is thus very important. While the latter can be influenced by temperature and pressure variations, the former remains constant, making mass flow measurement a key, and very convenient, parameter to drive an industrial process reliably. The difficulty of measuring mass flow for liquids and gases comes from varying densities and viscosities, requiring sophisticated technology to address these complexities. Coriolis flowmeters have fared particularly well in this matter, reaching generally good precision and reliability.

The Coriolis effect, a phenomenon arising from the interaction of mass and motion, is the base principle behind Coriolis flowmeters. These devices employ oscillating tubes, drivers, and sensors to capitalize on this effect for precise mass flow measurement. Oscillating tubes inside which circulates a fluid are equipped with sensing devices that measure the displacement of the tube at 2 points (one point upstream, one point downstream). When the fluid circulates, the tube is subject to forces proportional to mass flow rates, the displacement of the tube then is not the same anymore at the 2 points of measure. By measuring the tiny movements of the tubes due to the forces that exert the passing fluid, a mass flowrate can be calculated.

The deviation of the tubes while oscillating is very small, in the order of magnitude of 0.001 inch. This is very small and can be caused by any external disturbance, for example the temperature of the fluid and vibrations. That is why Coriolis mass flowmeters are equipped with temperature sensors (to correct the deviation due to temperature) and must be isolated from any vibration. One interesting feature though is that, as the flowmeter is measuring temperature, this can also be read by a PLC and thus save one temperature sensor.

Top

5 Most Popular

1. Pressure drop

2. Reynolds Number

3.

Pressure drop K coefficients

4. Churchill equation

5. Moody diagram

3.Advantages of Coriolis Flowmeters

Coriolis flowmeters have shown very good accuracy and repeatability, often outperforming alternatives. Their wide turndown ratio accommodates fluctuations in flow rates, eliminating the need for multiple devices. Reasonable pressure drop (although this should be checked as flowmeters generally use smaller pipe diameters than the main pipe to which they are integrated) ensures minimal disruption to the fluid system. Coriolis flowmeters' compatibility with diverse fluids, regardless of viscosity or density, extends their application range significantly.

Tube design of Coriolis flowmeters

- 1 or 2 tubes : There are design where the entire flow goes through one oscillating tube (continuous tube design), and design where the flow is split in 2 tubes (2 tubes design).

- 1 tube design : 1 tube design has an advantage when handling slurries which risk to separate in they go through 2 tubes. When the fluid has some particles, like in a slurry, as the continuous tube design has a larger diameter it is less prone to clogging

- Straight or bent tubes : it is possible to chose either straight tube designs (usually continuous tubes) and bent tube design (usually 2 tubes)

- Straight tubes : these design have numerous advantages such as being less sensitive to vibration, create less pressure drop and being easier to clean and easier to install. However they usually have lower working range and lower accuracy.

- Bent tubes : bent tubes cannot be mechanically cleaned, a CIP will be required with velocities > 3 m/s. They have however a better accuracy and range.

Recommended service for mass flowmeters (from Omega Engineering table)

| Service | Not applicable | Applicable but needs review | Good performance |

| Steam | X | ||

| Clean gas | X | ||

| Dirty gas | X | ||

| Gas high pressure | X | ||

| Gas low pressure | X | ||

| Clean Liquid | X | ||

| High visco liquid | X | ||

| Low visco liquid | X | ||

| Dirty liquid | X | ||

| Corrosive liquid | X | ||

| Very corrosive liquid | X | ||

| Fibrous slurry | X | ||

| Abrasive slurry | X | ||

| Reverse flow | X | ||

| Pulsating flow | X | ||

| High temperature | X | ||

| Cryogenic | X | ||

| Semi filles pipes | X | ||

| Non Newtonian | X | ||

| Open Channel | X |

4. Factors Influencing Performance

Fluid properties like viscosity, density, and conductivity significantly impact measurement accuracy. Additionally, the flow profile, influenced by piping and fluid behavior, can introduce inaccuracies. Proper installation practices, including mounting, grounding, and vibration isolation, play a pivotal role in achieving optimal performance.

Orders of magnitudes of accuracy that can be reached for Coriolis flowmeters, as a function of the size of the flowmeter:

- Small flowmeters (e.g., < 1 inch): High accuracy in the range of ±0.1% to ±0.2% of the actual mass flow rate.

- Medium-sized flowmeters (e.g., 1-3 inches): Accuracy of ±0.05% to ±0.1% of the actual mass flow rate.

- Large flowmeters (e.g., > 3 inches): Accuracy ranging from ±0.02% to ±0.05% of the actual mass flow rate.

In term of versatility, curved tube design can measure over a wide range of flow (up to 200:1) while newer designs with straight tubes, although they have their own advantage in terms of space occupation and easiness of cleaning, can only reach 50:1 with lower accuracy.

5. Selecting the Right Coriolis Flowmeter

Choosing an appropriate Coriolis flowmeter necessitates to consider several parameters. The following criteria guide the decision-making process:

- Fluid characteristics: Viscosity, density, corrosiveness, and abrasiveness.

- Flow rates: Expected minimum and maximum flow rates.

- Process conditions: Pressure, temperature, and ambient conditions.

- Environment: Hazardous or safe areas, indoor or outdoor installation.

- Communication and integration: Compatibility with existing control systems.

- Budget considerations: Initial cost and long-term maintenance expenses.

6. Installation and Maintenance

The installation of Coriolis flowmeters demands meticulous attention to detail. Proper mounting, aligned with fluid dynamics, prevents measurement distortions. Effective grounding and vibration isolation safeguard against external interferences. Regular maintenance, including tube cleaning and verification, ensures long-term accuracy, extending the device's lifespan.

7. Common Problems and How to Solve Them

| Possible Issues | Solutions |

|---|---|

| Entrained air in the fluid | Proper degassing or venting before flow measurement. |

| Fluid density variations | Regular calibration and adjustments for changing density. |

| Viscosity changes affecting accuracy | Compensation algorithms based on fluid viscosity. |

| External vibration and interference | Isolation and proper grounding to minimize disturbances. |

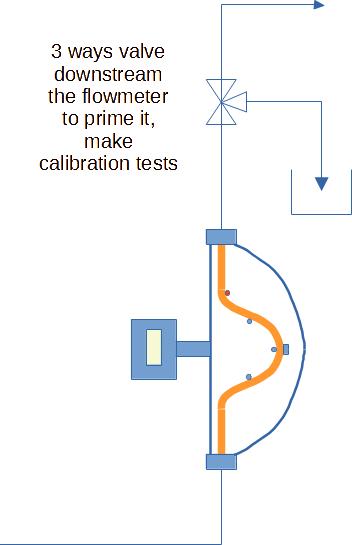

When using a Coriolis mass flowmeter for measuring the flowrate of a liquid, the presence of gas (for example air) can be very detrimental to the performance of the flowmeter and can lead to random and inaccurate results. It is very important to be able to fill properly a flowmeter, degas it completely, and keep it free of gas. Having purging points down the flowmeter, which can also be used for checking the calibration (provided the liquid is not hazardous), will help to fill the flowmeter and avoid these issues. It can be also interesting to mount the flowmeter vertically (flow upwards).

8. Applications in Liquid and Gas Flow Measurement

In the oil and gas sector, Coriolis flowmeters enable precise custody transfer, ensuring equitable transactions. In the pharmaceutical realm, they facilitate accurate dosing of critical ingredients. In food and beverage production, they aid in blending and batching processes, maintaining consistent quality. Their adaptability to both liquids and gases renders them indispensable in modern engineering.

Numerous industries have reaped the benefits of Coriolis flowmeters:

- Chemical sector: Accurate measurements facilitated efficient blending, minimizing waste.

- Oil and gas industry: Reliable mass flow data resolved custody transfer disputes.

- Food industry: Coriolis flowmeters ensured precise ingredient dosing, enhancing product consistency.

Source :