Piping Systems : free online Process Engineering Handbook

Process Engineer's Tools has selected here all the key knowledge Engineers working with fluid flow / fluid dynamics need to solve industrial problems or simply get a handy reminder when required. Bookmark the page for future reference !

PIPING SYSTEMS

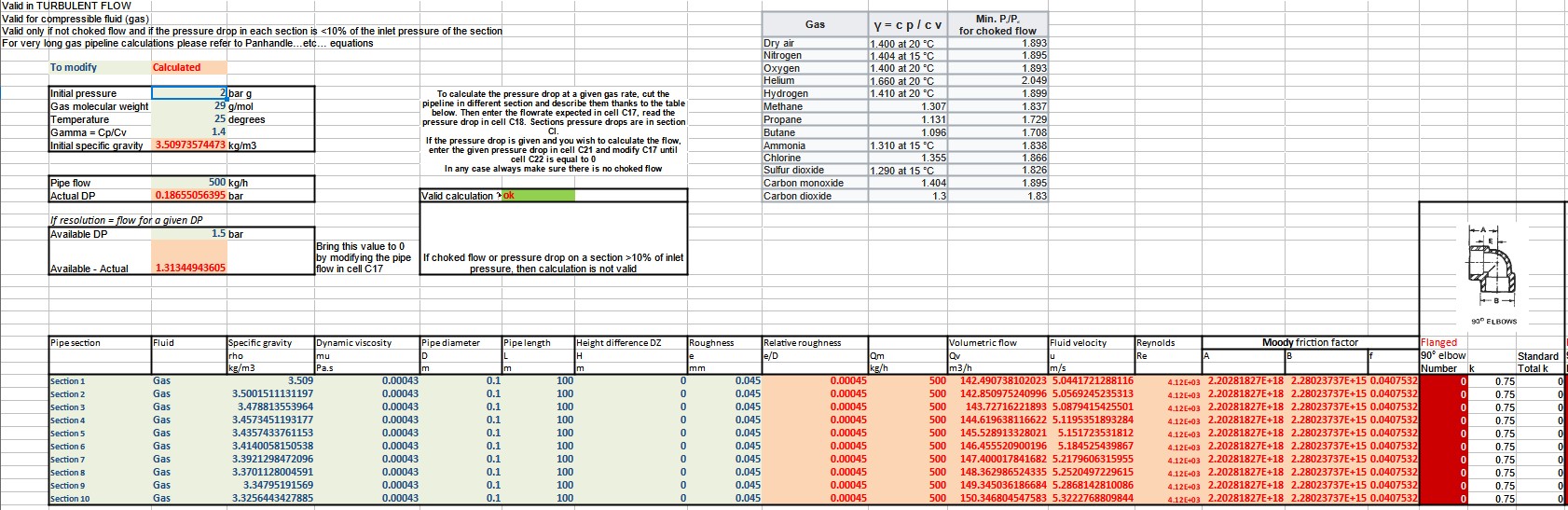

Discover pipe pressure drop principles and access free Excel calculation tools. Calculate pressure drop in straight pipes, factor in bends, valves, and more for comprehensive results.

Essential information on the equivalent length of common valves and fittings in piping systems, facilitating pressure drop calculations. It's a valuable resource for engineers and professionals looking to streamline preliminary studies or troubleshooting. Visit the page for detailed tables and data in both US and SI units to enhance your piping system design and analysis

Recommended K coefficient, which is used to calculate pressure drop in fluid piping due to fittings and valves in turbulent flow. It offers a range of K coefficients for various common valves and fittings, aiding engineers in precise pressure drop calculations. These coefficients are essential for ensuring efficient and accurate design of fluid piping systems.

References for laminar flow pressure drop calculations in fluid piping systems.Recommended K coefficients for pressure drop in valves and fittings in LAMINAR flow, offering two approaches. Kittredge and Rowley's data provides frictional loss coefficients for various Reynolds numbers, while Hooper's method offers an approximate approach by using coefficients for turbulent flow and laminar flow adjustments.

This webpage explains how to determine if a pipe is partially full, which is crucial for accurate calculations in scenarios like return pipes and condensate systems. An Excel calculator is proposed at the end of the article.

This article offers insights into gas sonic velocity and critical pressure ratios, along with a downloadable Excel calculator for sonic velocity estimation. Sonic velocity represents the maximum attainable gas speed within a system, impacting aspects like pressure safety valves and flow constraints. Formula in both metric and imperial units are given.

Overview of control valve types

commonly used in process industries, including globe valves, angle

valves, butterfly valves, gate valves, and ball valves. Each valve

type is briefly described, highlighting their specific design

features and typical flow parameters. We also give manufacturers

references for each valve type and give links to additional pages

for valve sizing calculations.

-

Valves Cv and sizing for liquid and gas

Control valve sizing, with a focus on

flow coefficients Cv and Kv, for both liquids and gases. It

explains the definitions of these coefficients and their

conversions. The calculations for flow through valves, considering

subcritical and critical flow conditions, are detailed for both

liquids and gases in SI units. The page also provides guidance on

control valve sizing, emphasizing maintaining a specific pressure

drop ratio and flow range. Corrections for special cases, such as

pipe reducers, viscosity, and laminar flow, are discussed.

-

Valves Cv and sizing for steam and superheated steam

Control valve sizing and flow

calculations, with a focus on defining Cv and Kv. The page

provides formulas for calculating mass flow rates of steam and

superheated steam in both SI and US units. Additionally, it offers

guidelines for optimal control valve sizing practices to ensure

efficient performance.

The webpage explains Cv and Kv

definitions for valve flow in SI units. It also explain how to

calculate the required Cv for valves in two-phase flow conditions,

considering factors like mass flow, geometry, and pressure drops,

aiding effective valve selection.

This article covers valve Cv

calculation for laminar flow conditions. It explains how to

correct Cv for such situations and provides detailed steps,

including calculations for factors like Reynolds number and

correction factor. You can use this resource to select the right

valve for laminar flow applications, ensuring precise control and

minimizing pressure drop.

Information on valve flow

characteristics, offering insights on different types such as

linear, exponential, semi-quick opening, and quick opening. The

article emphasizes the importance of selecting the right valve for

precise control and the factors affecting valve behavior within a

circuit. Valve gain and actuator torque considerations for optimal

performance are also discussed.

Top 5 Most

Popular

1. Compressor

Power Calculation

2. Pump Power Calculation

3. Pipe Pressure

Drop Calculation

4. Fluid Velocity in pipes

5. Churchill Correlation (friction

factor)

This guide provides insights into

pressure relief valve design and sizing, focusing on API 520

standards. It explains critical vs. subcritical flows and offers

formulas for safety valve sizing, especially for steam

applications. Engineers can select standard valve orifice sizes

based on standardized designations.

This guide explains pressure relief

valve design and sizing for low-pressure safety venting. It

outlines theoretical formulas and coefficients for calculating

valve flow. Note that this information is for low-pressure gas

applications only.

This guide explains pressure relief

valve design and sizing for liquid flow, emphasizing safety. It

provides formulas and coefficients for calculating valve

requirements based on API520 standards.

All about hydrostatic pressure – the force exerted by resting fluid due to gravity : calculation formula of hydrostatic pressure, table for pressure vs. water depth and practice problems. Access the Hydrostatic Pressure calculator in Excel.

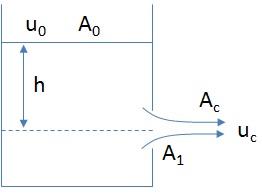

Understand Torricelli's Law for tank orifice flowrate. Calculation of liquid flowrate with the Torricelli formula, with worked examples. Calculation of the time to empty a tank using Torricelli's equation, with worked example.

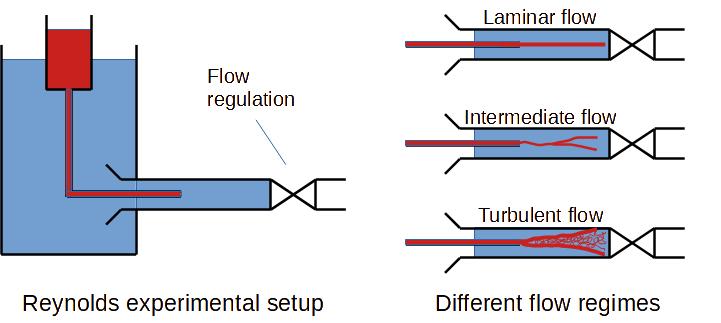

Calculation of Reynolds number

The hydraulic diameter concept

simplifies non-circular flow calculations. It is useful for

Reynolds number and flow regimes (laminar, intermediary,

turbulent). Access an Excel Calculator for hydraulic diameter.

Learn about the friction factor in

pipes and how to calculate it. Understand its significance in

fluid flow and explore formulas for laminar and turbulent regimes,

including the Hagen-Poiseuille equation.

Discover the difference between Fanning

and Moody friction factors in pipe flow. Learn how to calculate

them and their significance in understanding fluid-pipe

interactions. Explore correlations and the Moody diagram for

practical insights.

This page explains what is the

Colebrook equation, a valuable tool in fluid mechanics, relating

it to Reynolds number and pipe wall roughness. Get the calculation

formula and understand its significance in estimating pressure

drop and explore alternatives like the Darcy-Weisbach and

Hazen-Williams equations.

You can calculate friction factors for

various flow regimes using the Churchill equation. Easily estimate

pressure drops in pipes from laminar to turbulent flows. Download

our free Excel calculation tool for Churchill correlation to

simplify your calculations and streamline your work.

Efficiently calculate pressure drop in

pipes with our handy tools. Understand the principles: it's the

sum of friction along straight pipes and singularities like bends

or valves. Simplify your work with our Excel calculation tools for

both liquid and gas flows.

Understanding fluid velocity in pipes

is crucial for flow characterization and sizing. Calculate it

easily with our Excel tool. Recommended velocities for common

fluids provided. Make informed design decisions for efficient

pressure and cost balance.

The different flow regimes in pipes as a function of Reynolds number

How to size and calculate orifice

plates for precise fluid flow control and measurement. You can

access our Excel calculation tool to practice the concepts

presented in the page

Learn how to calculate motor power for a tank agitator step by

step. Find a free Excel calculator for agitator power requirements.

This article provides a comprehensive guide to flow meter installation and usage, covering selection criteria, installation processes, and type-specific guidelines for various flow meters. It addresses challenges such as high-viscosity fluids, temperature effects, and common metering issues, along with maintenance requirements and application considerations.

Learn about Coriolis mass flowmeters, their advantages, and factors affecting performance. Discover how to select, install, and maintain them for accurate fluid flow measurement in various industries.

Learn about water hammer, a sudden pressure increase in fluid-carrying pipes caused by rapid flow changes. Discover its consequences, the calculation of pressure rise, and prevention methods to safeguard pipes and equipment from damage. Access a an Excel calculator for pressure rise prediction

This page is presenting the importance of recommended velocities in water pipe networks. You can understand why following these guidelines is crucial for energy efficiency and system performance. Calculate water flow velocity with our Excel tool.

This page is explaining step by step how to calculate the time required for a pitch blade agitator to homogenize a liquid mixture.

Learn about terminal velocity in fluid mechanics. Understand how to calculate it for single particles and in the presence of other particles. Check out our Excel calculator for testing the concepts presented in the page.

This page is explaining step by step how to estimate the apparent viscosity of a fluid from the power that is applied to a double helix agitator.

This article is presenting non-Newtonian fluids, where viscosity isn't constant but varies with shear rate. Learn about time-independent and time-dependent non-Newtonian behaviors, and explore the unique properties of viscoelastic materials.

Gain a comprehensive understanding of hoses, their types, and how to calculate pressure losses in fluid transport systems. Explore the diverse materials, designs, and classifications of hoses, from rubber to stainless steel. Learn how factors like length, diameter, flow rate, and fluid viscosity contribute to pressure loss. Follow a step-by-step guide to calculate pressure loss using the Darcy-Weisbach equation. Whether you're dealing with rubber, PVC, or thermoplastic hoses, this guide equips you with essential insights for efficient system design.

Unlock the potential of check valves in piping systems with our comprehensive guide. Explore swing, lift, ball, and diaphragm check valves—understand their design, installation, and troubleshooting. Delve into critical considerations like material selection, sizing, and cracking pressure. Learn to address common issues such as backflow, water hammer, and excessive wear. Our detailed guide ensures you master the intricacies of check valves.

Explore the world of check valves in piping engineering—essential components ensuring fluid flows in a single direction. Discover the diverse designs available and their applications. Uncover the common issue of noisy check valves and learn the importance of proper design to avoid quick wear. Delve into a step-by-step guide for calculating the minimum pipe velocity needed for full disc lift in check valves. Access a practical Excel calculator for quick and accurate calculations.

Explore the crucial role of steam traps in process industries, understand common failure modes, and learn how to calculate steam leakage. Access an Excel calculator for precise steam loss estimations and discover cost-saving strategies.

Explore efficient methods for calculating pressure drop in long gas pipelines. Learn about isothermal, Weymouth, Panhandle equations, and a modified isothermal approach. Access an Excel calculator for gas flow estimations.

Learn essential principles for designing hygienic piping systems in food and pharma industries. This page covers key practices like eliminating dead ends, ensuring smooth surfaces, and selecting proper couplings and valves. Discover how to prevent material accumulation, optimize cleaning efficiency, and maintain product quality. For comprehensive guidance on hygienic piping design, visit the website

Discover essential principles for effective Cleaning in Place (CIP) systems in food industries. Learn about the 4 Ts: Time, Temperature, Titration, and Turbulence, crucial for thorough cleaning. Understand the sequence of cleaning steps and safety measures. Explore key considerations for hygienic design, including pipe design and dead end prevention.

Comprehensive guide to Cleaning-In-Place (CIP) systems using spray balls in food and beverage production. It covers the working principles, types of spray balls (static, rotating, multi-jet, sanitary), and selection criteria based on tank geometry, soil type, and regulatory requirements. The article provides detailed design parameters, including pressure, flow rates, and material choices, alongside a step-by-step procedure for sizing and placing spray balls. It emphasizes validation, maintenance, and practical considerations for ensuring effective and compliant cleaning performance.

Explore power numbers for various agitator types essential for effective tank agitation. Learn how power numbers facilitate calculating the required shaft power for agitation. Understand the importance of knowing the power number for efficient mixing and troubleshooting. Discover estimated power numbers for common agitator geometries, aiding in preliminary calculations when pilot trials aren't feasible

Discover pumping numbers for common agitators crucial for efficient tank agitation. Learn how to calculate pumping flow and understand its significance in ensuring proper fluid circulation. Find references for pumping numbers to aid in preliminary calculations, especially when pilot trials aren't feasible. Explore agitator types and their associated pumping numbers for effective tank mixing.

This article explains why rheology must be part of everyday process design for non-Newtonian fluids in pipes and equipment. It starts by contrasting Newtonian and non-Newtonian behaviour, showing how shear-dependent viscosity breaks the simple “single viscosity” design approach used for water-like fluids. It then defines shear rate in pipe flow and highlights the trap of using the nominal expression 8V/D, which is only exact for Newtonian laminar flow and underestimates wall shear rate for shear-thinning systems.

The article introduces the Weissenberg–Rabinowitsch–Mooney correction to convert nominal to true wall shear rate and explains how to use the flow behaviour index to obtain realistic apparent viscosities for design. Finally, it links corrected shear rate and rheological data to practical outcomes: pressure drop prediction, pipeline sizing, pump selection, flow regime assessment, and scale-up, emphasising how skipping this step can lead to blockages, unstable operation, and unnecessary cost.